+ Weigh Fillers

+ Steel Container

+ Feeders

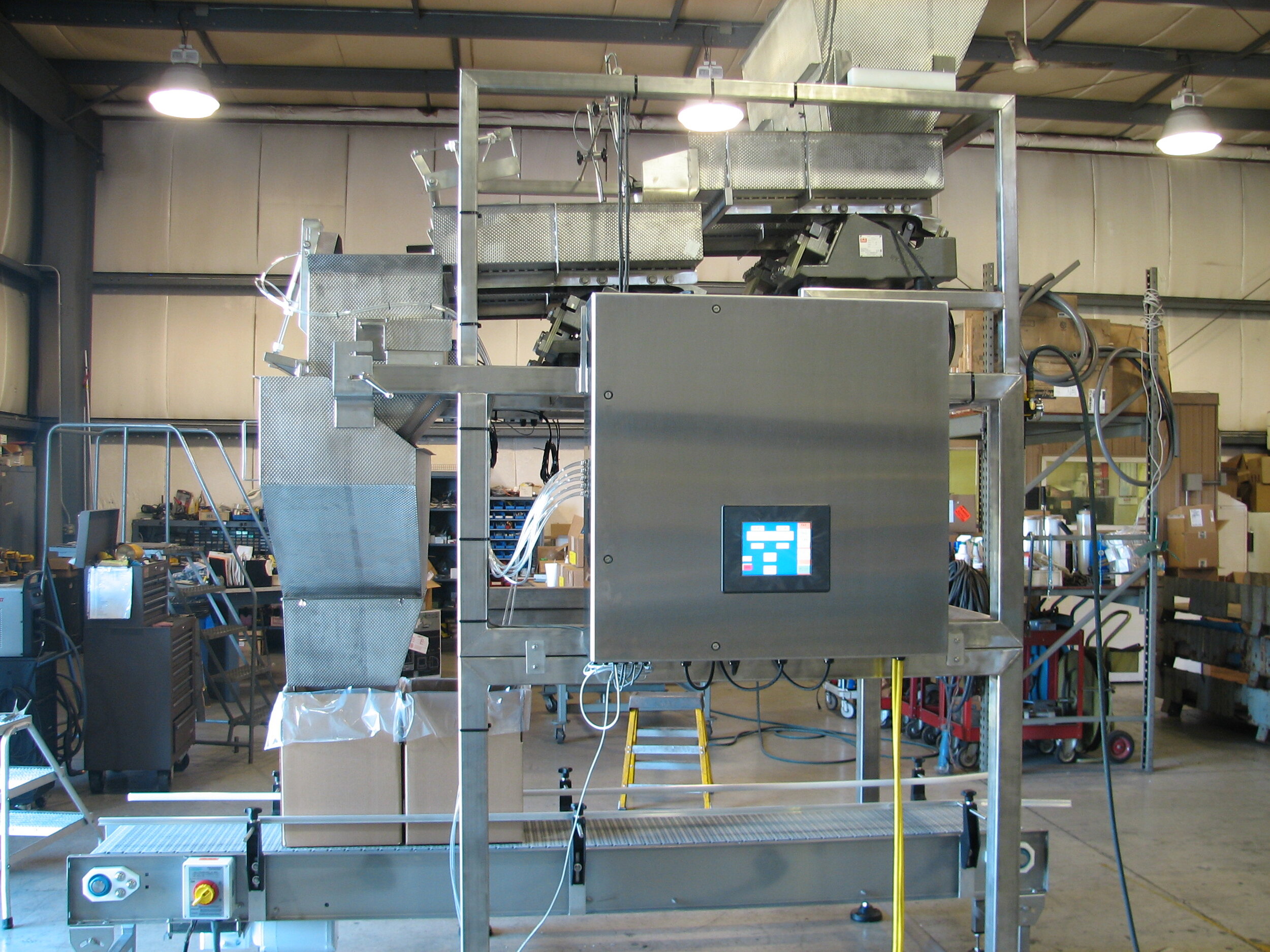

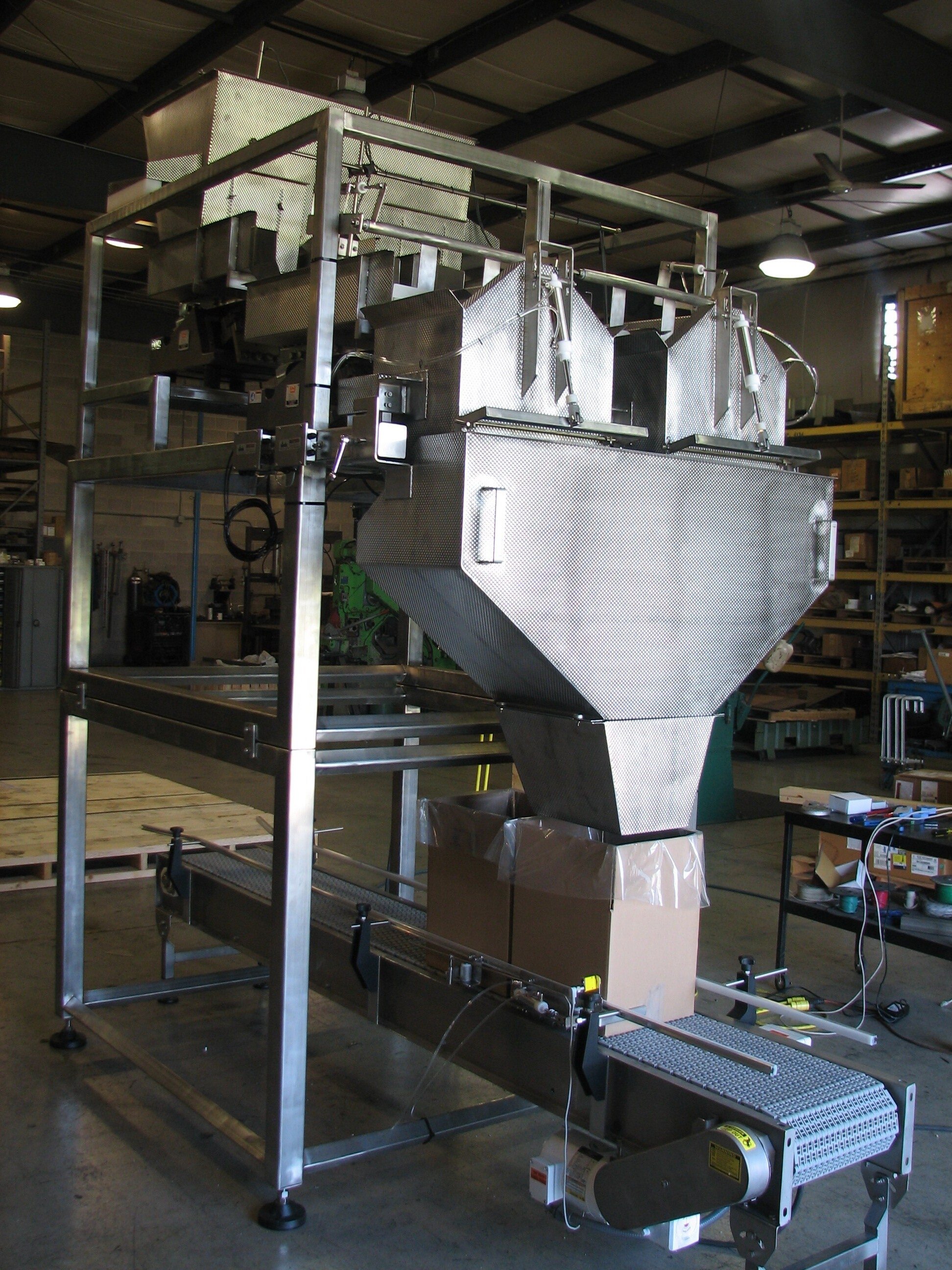

Powell AWC

The Powell AWC Series can handle most any type of product that will move over a vibratory feed pan. The product moves over a vibratory feed pan (or several feed pans) into a weigh hopper. The hopper is mounted on one or two strain-gauge load cells that communicate with the microprocessor. When the programmed weight is reached, the vibratory feed stops and the hopper dumps into a bag, box or other selected container.

Changeover to different size and types of packages is quick and easy. Packages will never be under weight and giveaways can average less than 1/8 oz. for smaller pieces.

Watch our video 1

Watch our video 2

Read a review from Packaging Digest.

For certain products with a uniform piece weight, the AWC Series also can be set up to package a specific piece count. In many instances, the versatile AWC Series can handle a variety of products and package types with the same machine. Package weight capabilities range from less than one pound to over 50 pounds-fresh, frozen or dry. All surfaces are stainless steel and high-pressure washdown rated. Each AWC system is USDA and

dairy-grading approved.